- Home

- Products

- Can Beverage Filling Machine

- Glass Bottle Beverage Filling Machine

- Juice Glass Bottle Filling Machine

- Carbonated Beverage Filling Machine

- Beer&Wine Glass Bottle Filling Machine

- Dairy Product Glass Bottle Filling Machine

- Coffee Glass Bottle Filling Machine

- Three Screw Cap Glass Bottle Filling Machine

- Four Screw Cap Glass Bottle Filling Machine

- Aluminum Screw Cap Glass Bottle Filling Machine

- Metal Crown Cap Glass Bottle Filling Machine

- Wood Cork Glass Bottle Filling Machine

- Water Filling Machine

- Plastic Bottle Beverage Filling Machine

- Water Treatment System

- Packing Machine

- Edible Oil Filling Machine

- Mixing System

- Strerilization System

- Juice Auxiliary Equipment

- Carbonated Beverage Auxiliary Equipment

- Bottle Blowing Machine

- Injection Molding Machine

- 6in1 Medium Temperature Aseptic Filling Machine

- Can Beverage Filling Machine

- Why Choose RISTON?

- Turnkey Project

- Packing Solution

- Labeling Machine

- Rotary Jam Filling Line

- Oil Filling Line

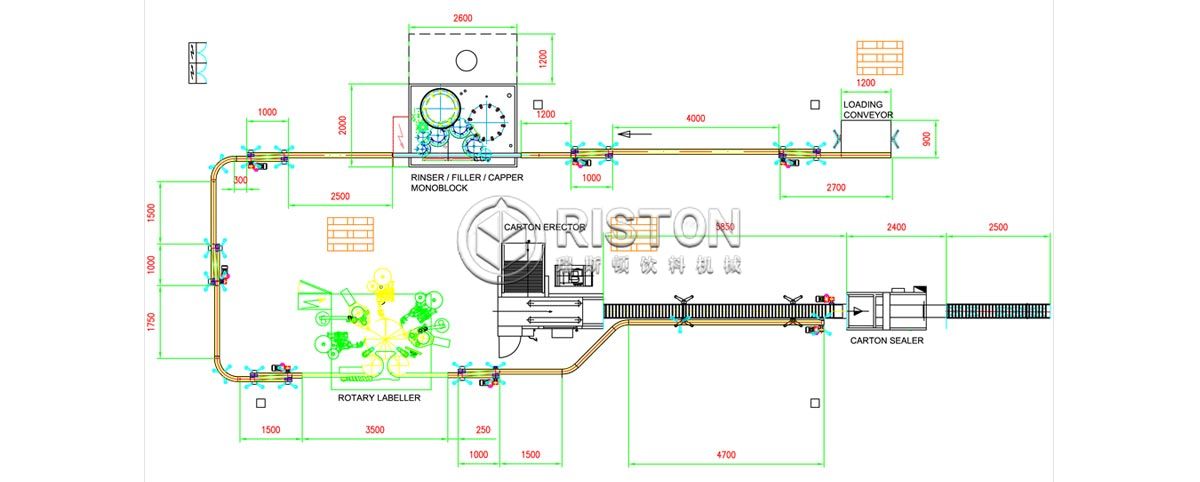

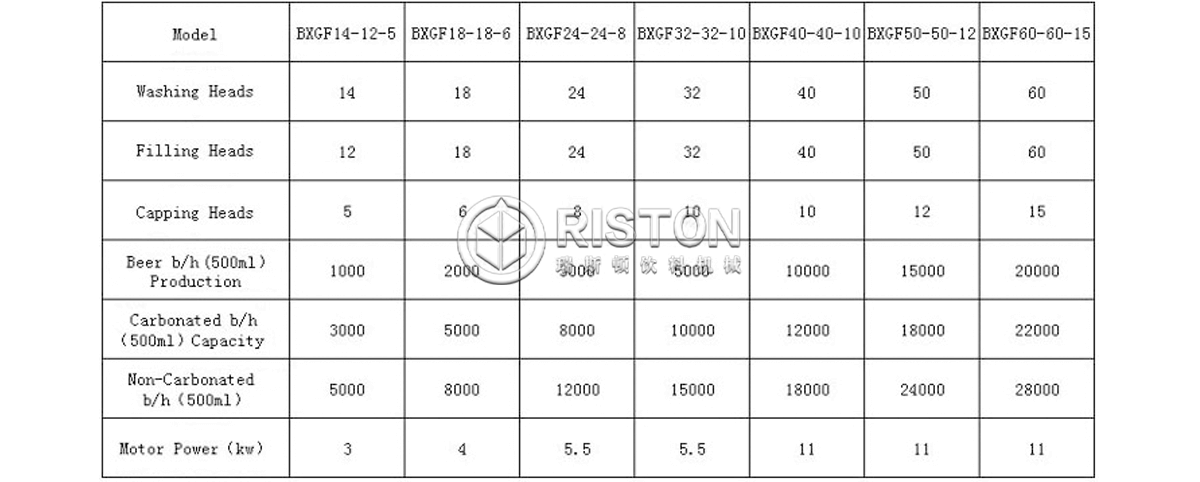

- Glass Bottle Wine Filling Line

- Glass Bottle Juice With Pulp Hot Filling Line

- Juice With Pulp Hot Filling Line

- Glass Bottle Juice Filling Machine

- Pet Juice Filling Line

- Can Juice Filling Line

- Can Carbonated Drink Filling Line

- Glass Bottle Carbonated Drink Filling Line

- PET Carbonated Drink Filling Line

- 5 Gallons Water Filling Line

- 330ml-1L Water Filling Line

- 3-10L Water Production Line

- About Us

- Contacts