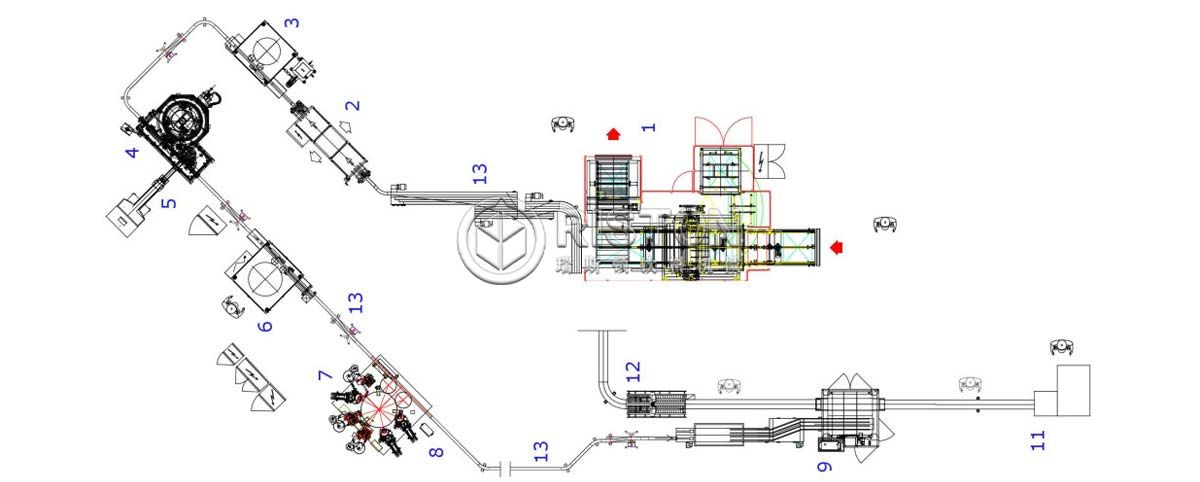

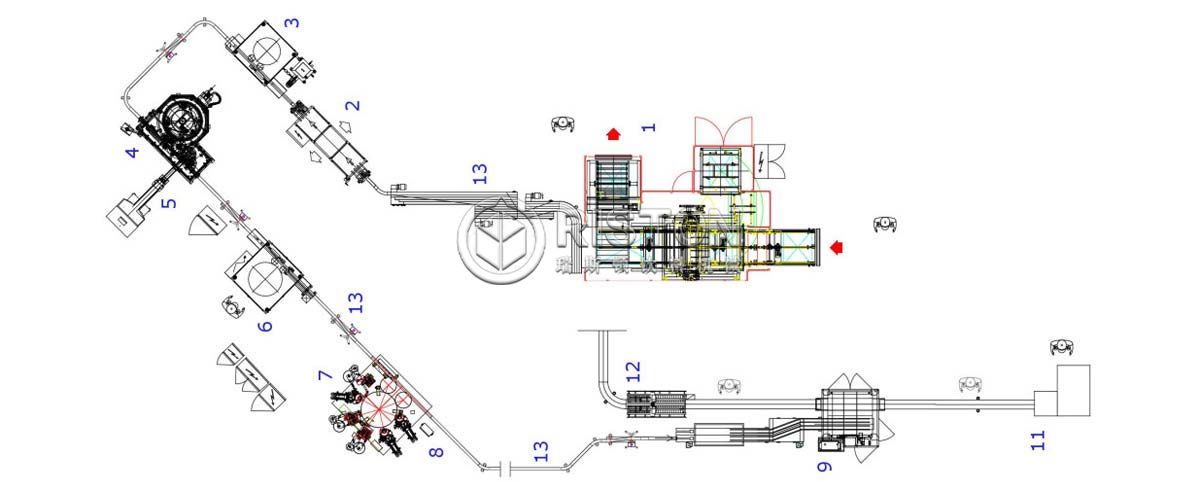

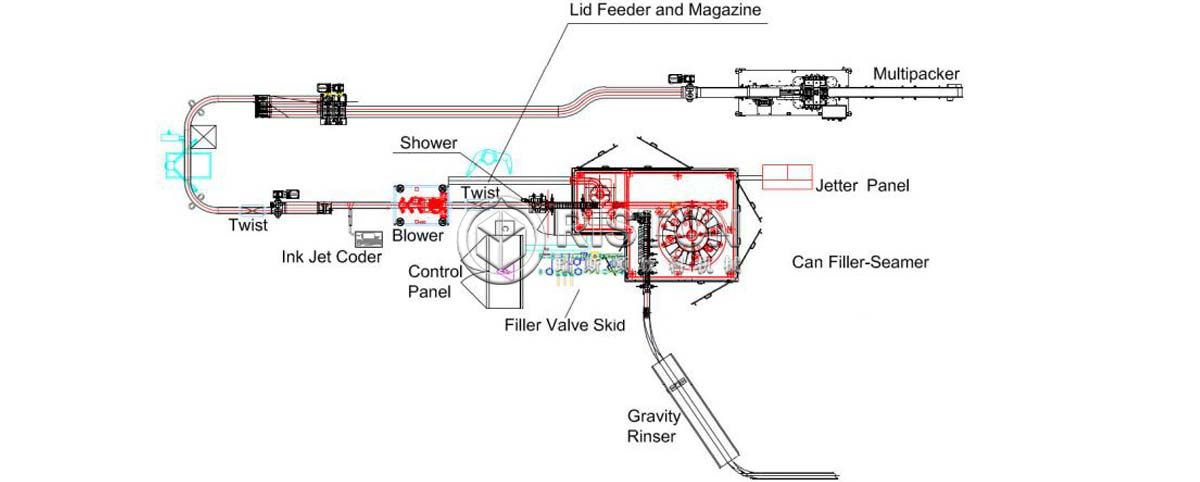

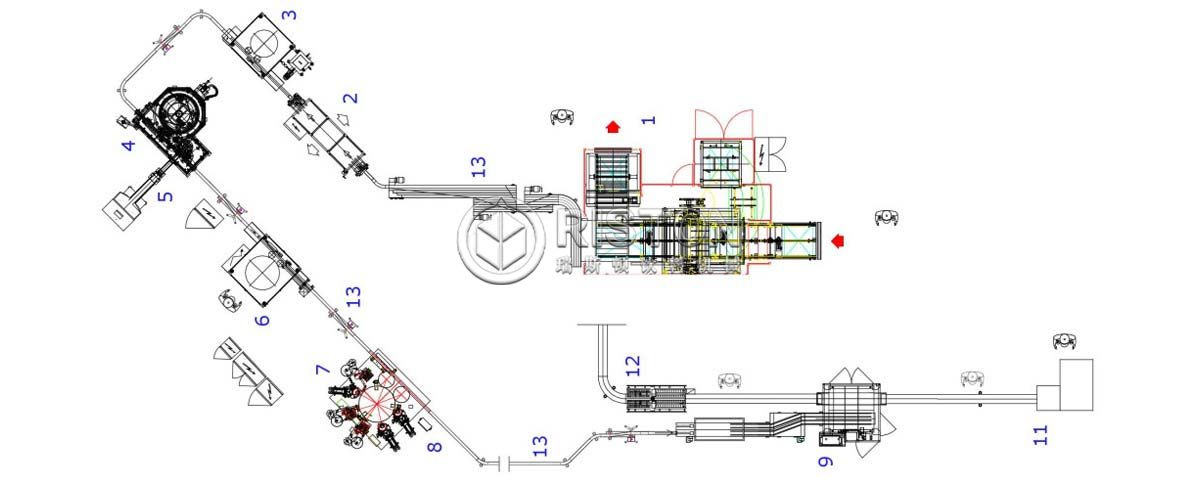

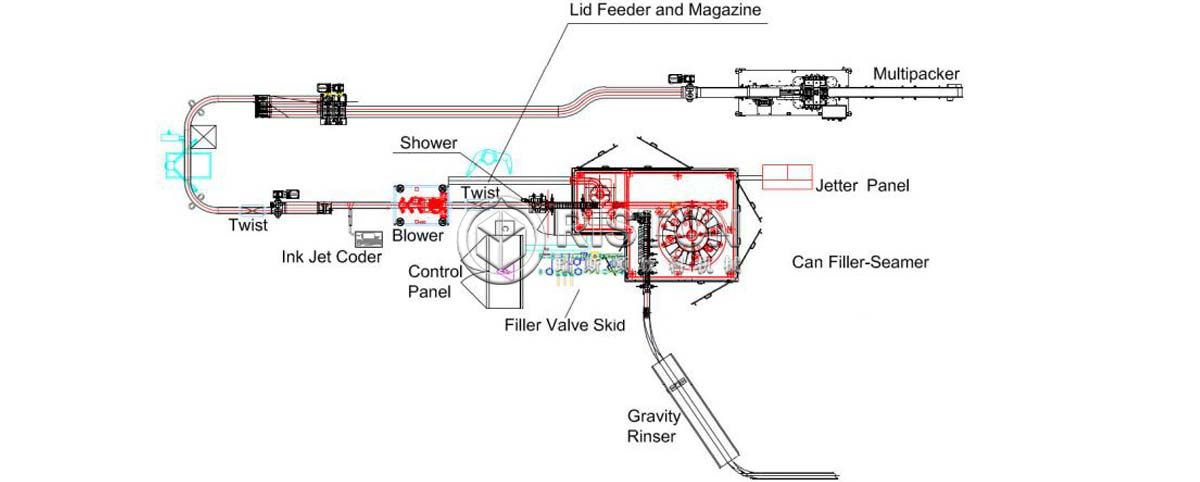

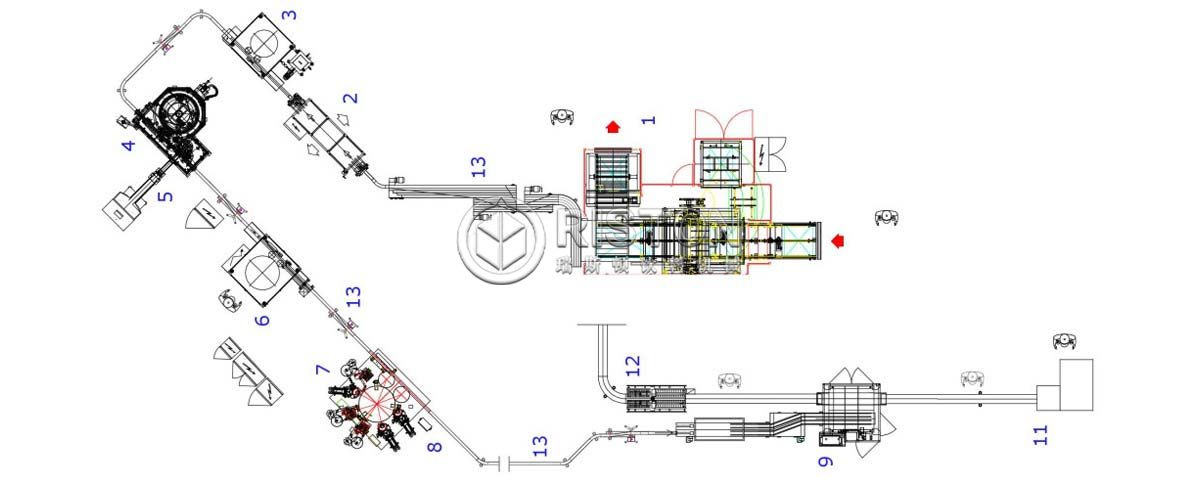

Related Equipment

Our state of the art filling and capping technologies are designed to maintain carbonation, minimize oxygen pick-up, pollution bacteria, beer lost, and CO2 consumption.

Beer is respected either for the big bottling plants either for the nice beer producers, at the lowest production costs.

We offer the most endearing labeling and secondary packaging solutions for clients success. Our turnkey plants are designed to offer the best efficiency in terms of flexibility and cost effectiveness with fast format change tools and robot palletizer islands.

Bottles driven by variable pitch screw are transferred to rinsing part through bottle-inlet star wheel. Nylon bottle holders nip the bottle necks and rotate 180°along a slideway to make the necks upside down. In certain area of rinsing part, the spraying nozzles spray water to rinse the internal surface of the bottles. After rinsing and dripping, bottles are rotated 180°again along a slideway to make the necks upward. Then bottles are transferred to filling part through the star wheel. Bottles will contact and lift the filling valves by bottle holder lifting device, thus filling passages are opened.